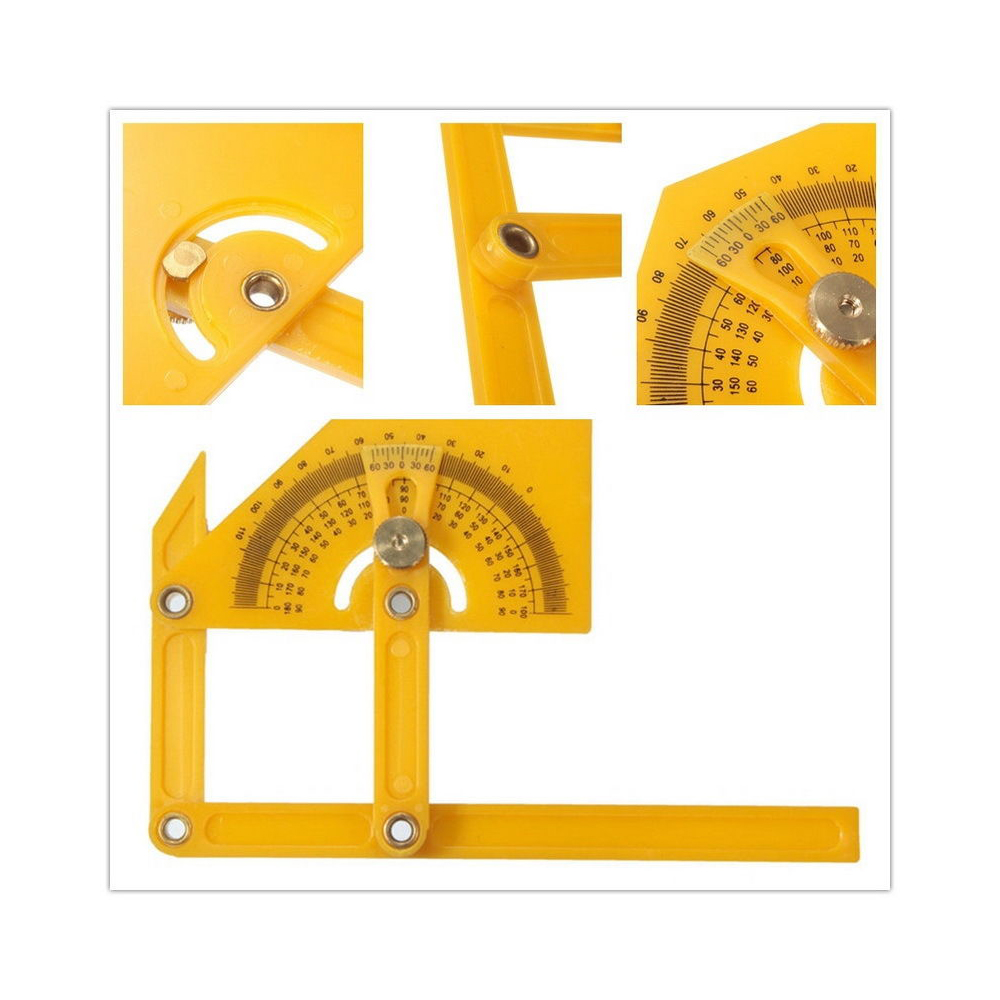

It can measure angle very precisely up to 5 arcminutes and can measure angle up to 360 degrees.The blade of the bevel protractor travels inside the slot present in the stock. The other side of the job surface whose angle is to be measured is kept in contact with the blade.

The job or workpiece whose angle is to be measured is kept in contact with this stock on one side. As it moves the dial also rotates with respect to the blade and the angle value is changed in the dial scale. The stock is the integrated part of the dial. Stock: The stock is one of the contacting surfaces in the bevel protractor while measurement of angle.This screw is used when we set the required length of the blade with the surface of the workpiece. Blade locking screw: A blade locking screw is available to lock the blade at a certain place.One side of the blade has an edge of 45 degrees and the other side has an angle of 30 degrees so that 45 degrees and 30 degrees can be directly measured using these edges. When the blade is parallel to the stock the zero of the vernier scale matches with the zero of the main scale or the dial scale. This blade is either 150 mm or 300 mm depending on the bevel protractor. Blade: This blade is made up of high carbon steel.These 360 degrees is divided into four divisions each of 90 degrees. In this graduated scale, every tenth degree is numbered. It contains the graduated scale of angle from a value of 0 degrees to 360 degrees. Dial scale: This dial scale is the main part of the bevel protractor.The main scale or the dial scale is marked over this dial. Dial: This is the base of the bevel protractor over which the other parts are present.

angle locking screw stops the swivel plate from rotating with respect to the dial or dial scale.

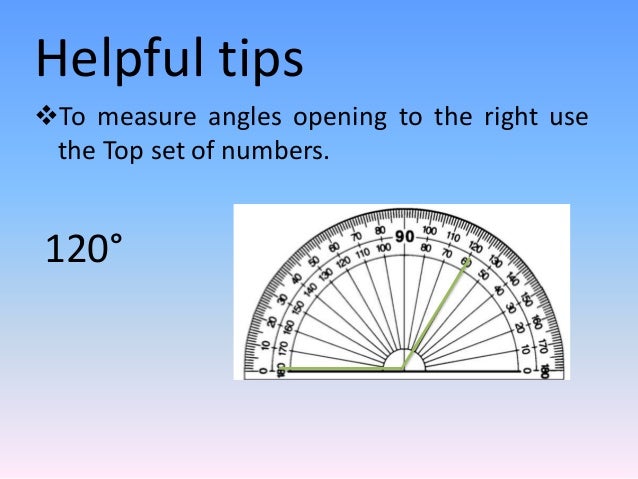

Vernier Scale: The vernier scale is fixed on the swivel plate and it moves with the swivel plate.This magnifying glass is used to see the value of the angles in the main scale and the vernier scale more clearly. Magnifying Glass: The swivel plate also has a magnifying glass present over the vernier scale.This swivel plate has a vernier scale which is integrated into it. Swivel plate: The swivel plate rotates over the dial.With these values along with the least count of the Vernier bevel protractor, we can calculate the Reading. this reading is noted as the Vernier scale reading. While taking a measurement, The Zero line on the vernier scale shows the reading on the main scale, called the main scale reading.Īt somewhere the divisions on the vernier scale will coincide with the divisions on the Main scale. One division on the Vernier scale = 1.91666° = 1° 55′ (one degree 55 minutes).Īs similar to the vernier caliper working principle as Zero on the vernier scale moves on the main scale. On the Main scale, the same portion is represented as 23° (12 divisions on the vernier scale = 23° on the main scale).

0 kommentar(er)

0 kommentar(er)